Trysilpanel – sustainable panelling that can be returned and reused

- Homepage

- Products

- Trysil panel

Trysilpanel (the Trysil panel) represents a natural solution to the construction industry's environmental challenges.

This reinterpretation of a Norwegian classic breaks with the idea that building materials have a one-time-only function. Vyrk has developed a panel that can be dismantled, returned and transformed – an environmentally friendly material designed for multiple lives in different rooms.

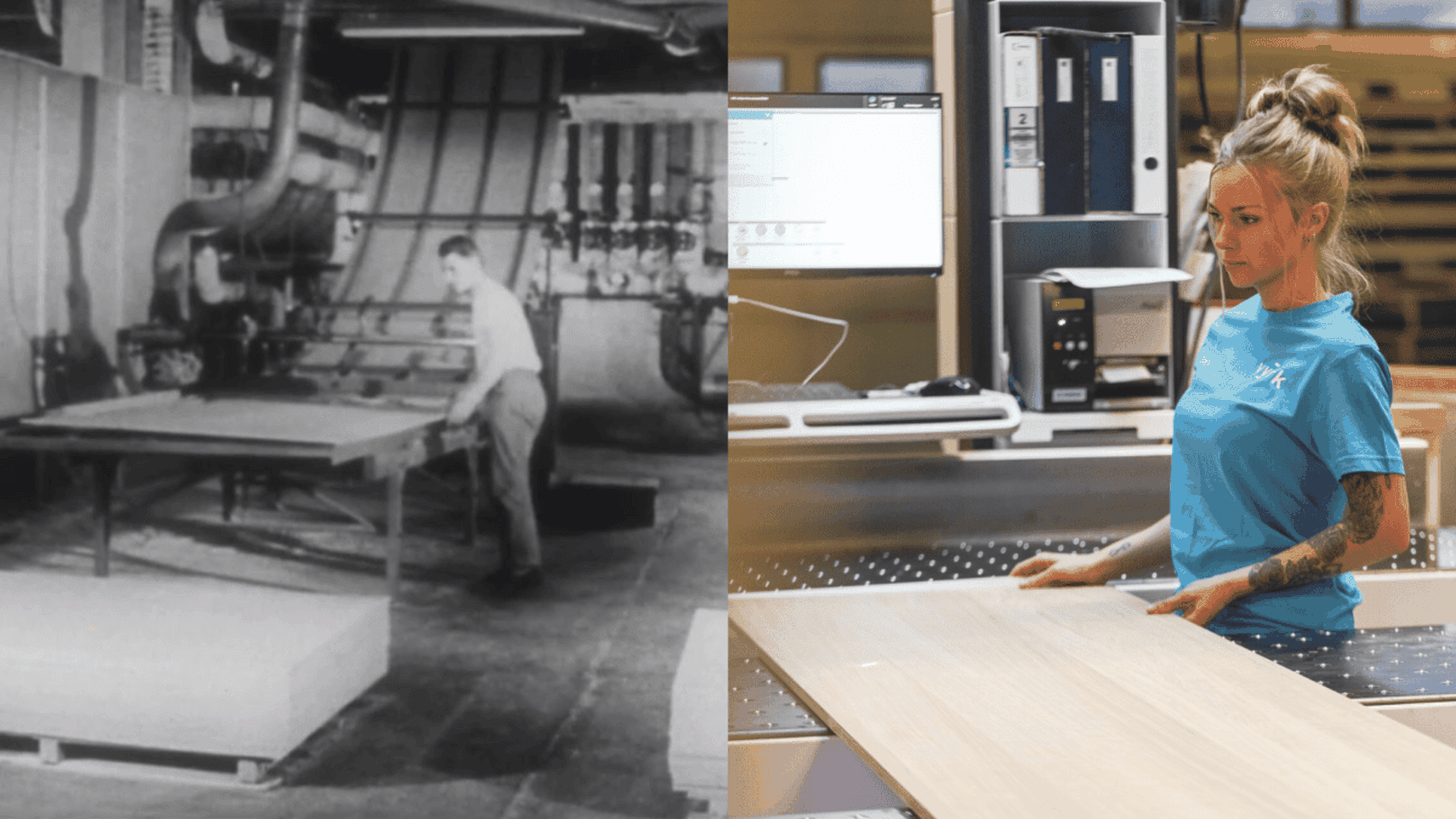

From iconic past to sustainable future

Based on the legendary Trysil panel – which has defined Norwegian interiors for generations – Vyrk has launched an ambitious reinterpretation. Six decades of veneer production at the Trysil plant has culminated in a product that breaks with the construction industry's use-and-discard mentality.

The Trysilpanel creates exclusive rooms while reducing raw material extraction. In principle, it can last forever, and acts as a long-term carbon storage system throughout its entire long lifespan. Thus, the panel stands in contrast to the very premise of the limited lifespan of building materials – a silent but effective showdown with the logic of consumer culture.

The deposit system – environmentally friendly material management in practice

In contrast to the construction industry's traditional one-way flow of materials, Vyrk is introducing a deposit system that makes Trysilpanelet part of a sustainable circular economy.

This six-step model shows how wall panels can have an extended life:

1. The panel is purchased

Vyrk sells the Trysil panel with a deposit included in the price. The collateral is managed by the manufacturer until repayment – a financial structure that ensures material circulation.

2. Mounting the panel

The panel is installed with a concealed rail system that enables future dismantling and relocation – either to other buildings or as part of modified space solutions.

3. Dismantling the panel

At the end of use, the panel is returned so that it can continue its life in other spaces and contexts – a practical implementation of material circulation.

4. Return points

Vyrk operates with four strategically located return points for the Trysilpanel at our production facilities in Rogne, Stange, Brumund and Trysil.

5. Returning the deposit

When the panels are handed in at one of our production facilties, the deposit is returned to the customer's account – a financial incentive for environmentally responsible material management..

6. Vyrk renews the panel

In the final phase, the panel is renewed. It can either be given a new look with veneer of oak, birch or walnut, or ground into a new core – thus ensuring almost eternal life

Benefits of the Trysilpanel

Targeted environmental awareness: Vyrk's goal is to create the market's most sustainable panel

Material honesty: Core of recycled wood materials with a veneered look

Circular lifecycle: The panel is sold with the building materials industry's first deposit scheme

Aesthetic diversity: Surface treatment in five different colours on most types of wood

Technical integrity: The panel can satisfy fire-safety requirements, so sustainability is assured

Easy mounting and dismounting: Using our intelligent rail system

Benefits of the Trysilpanel

Targeted environmental awareness: Vyrk's goal is to create the market's most sustainable panel

Material honesty: Core of recycled wood materials with a veneered look

Circular lifecycle: The panel is sold with the building materials industry's first deposit scheme

Aesthetic diversity: Surface treatment in five different colours on most types of wood

Technical integrity: The panel can satisfy fire-safety requirements, so sustainability is assured

Easy mounting and dismounting: Using our intelligent rail system

Own colour palette for Trysilpanel

The Trysil panel is available in the most sought-after wood species such as oak, walnut, birch and ash, and comes in a dedicated colour range to suit different architectural looks.

Standard dimensions of 12.7x240x2400 mm and 12.7x240x3000 mm for rail system and 12.7x230x2400 and 12.7x230x3000mm for tongue and groove, ensuring compatibility with modern building standards.